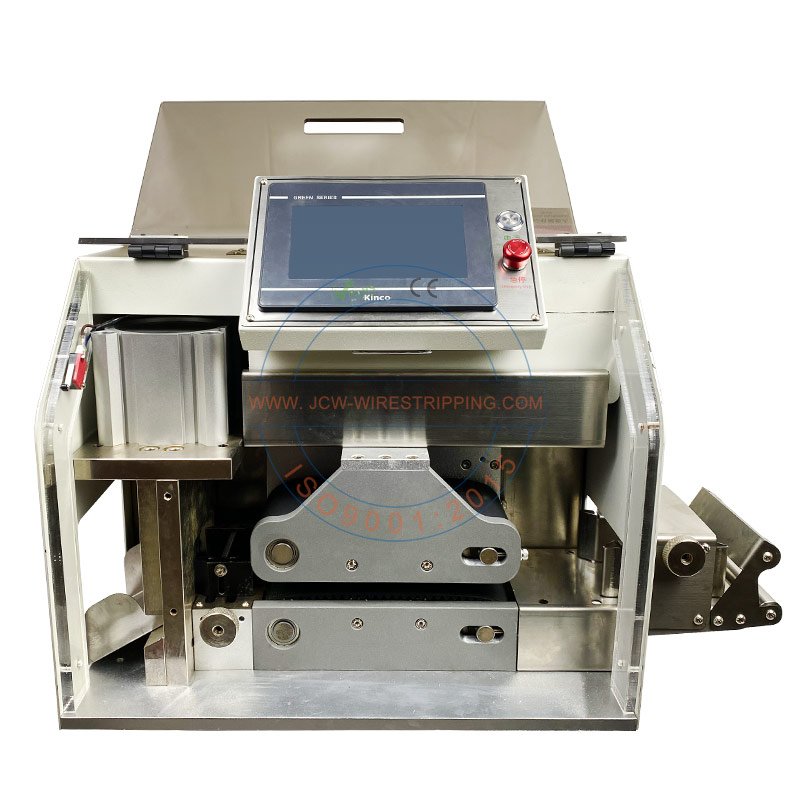

Fully programmable heat shrink tube processing device

Cut, strip, crimp, print & shrink all in 1

Ferrule crimping is available, only on request

Compatible with all China OTP crimp applicators

Customizable for adapting Europe mini-style applicator

High price-performance ratio

Ultra-compact design, high efficiency

10" touch screen user-friendly operation system