JCW-CS06 High-speed Comprehensive Wire/Cable Cut and Strip Machine

6 rollers cable feeding system, versatile cut & strip platform

Versatile cut & strip machine

The JCW-CS06 is a comprehensive wire cutting and stripping model for processing various single wire, multicore cables. It perfectly suits the wire harness factory and end-users who have various wire types, and wish to process all in one machine. Each CS06 comes with a complete set of guide tubes that cover a wide range of wires at different diameters, fast changeover optimizes the cable cutting and stripping, guaranteeing the same precision.

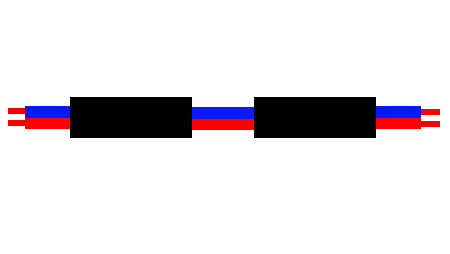

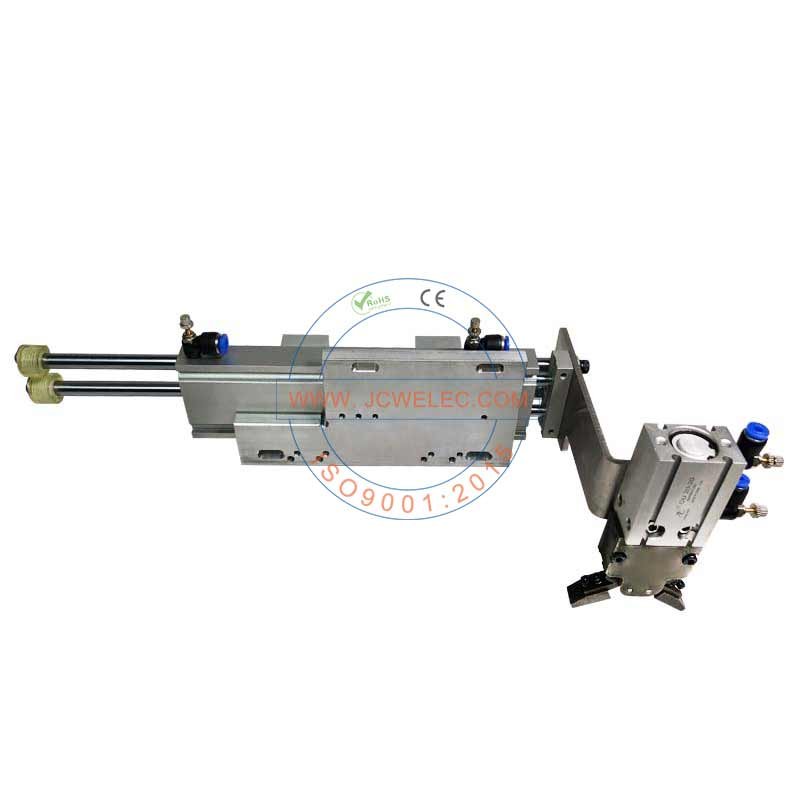

Base on the standard model, we developed JCW-CS06Z, which is specifically for parallel placed 2 core twin flat cable. It allows cable slitting, cutting, and dual-end stripping in one work cycle. The slitting length is programmable, and the slitting unit is specially made for specific cable gauge, it guarantees the slitting precision with no damage to the conductor.

Easy to use

The standard model comes with an English display, the machine language is customizable. A user-friendly interface and color touchscreen make the operation so accurate and simple.

- The control with touch screen has an intuitive user interface for simple and safe operation.

- The parameters such as wire cutting length, stripping length, wire diameter, speed, etc. can be accurately entered and stored for future recall at any time.

- Data library saves 100 programs, you can name each one by a wish.

- This cutting and stripping machine features an automatic one-touch calibration function for cutting length.

- Wire run-out sensor gives the machine a stop signal while the wire is used out.

- Quickly change guide tubes and cutter blades.

Various options for specific applications

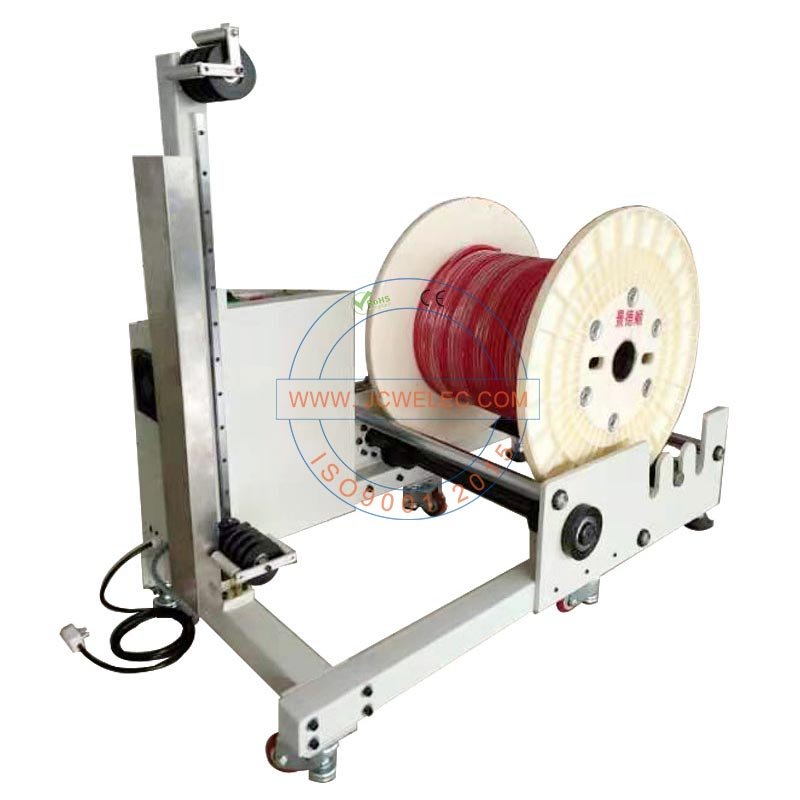

- Wire unwind & pre-feed machine, load range from 15 to 1000 KG

- Robot arm controlled by CS06

- Cable stacker, 1 meter to 6 meters

- V-blade, Multi-V blade, Radius blade, Flat blade

![Automatic Battery Cable Cutting Machine [ 8 Rollers ]](/data/thumb/res/en/20250509/jcwelec-cs05-cable-cut-strip-machine_1137102b.jpg_20250509172909_800x800.jpeg)