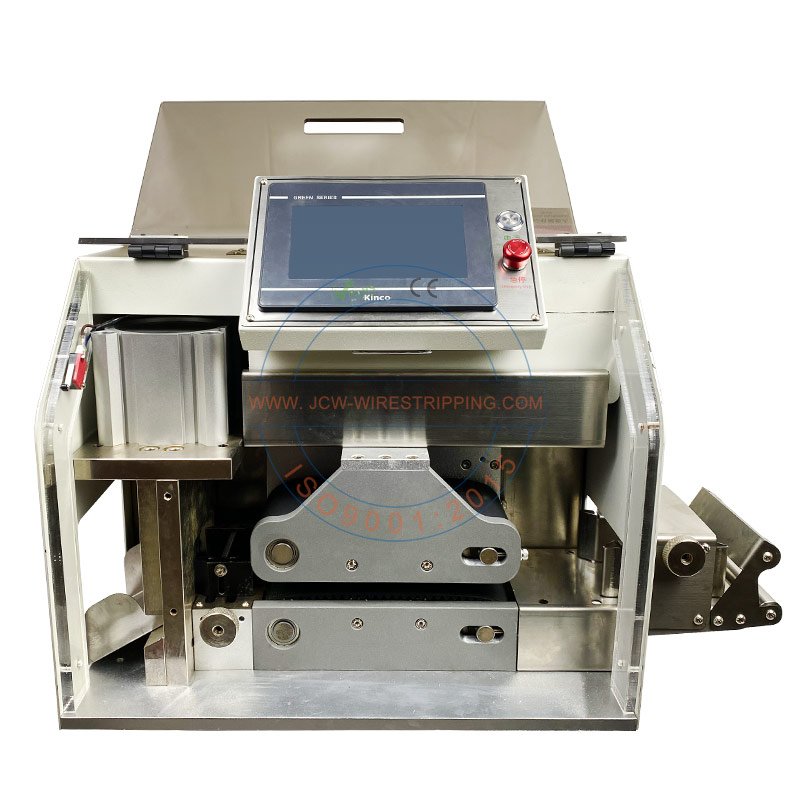

Shrinkage by infrared radiation for heavy-duty heat shrink sleeves

360 degree shrink without turning the cable

Induction trigger, automatic heating

Zero burning, fully safe,

More energy efficient than a standard heat gun

Overheating and overload protection

Material dimensions φ100 x L130mm