Cut, form, and crimp

30 KN crimping force

Motorized feeding splice band

Various interchangeable toolsets

Apply to various splice band material

Various applications all with a strong connection

Simple to operate

JCW-2TA

Cut, form, and crimp

30 KN crimping force

Motorized feeding splice band

Various interchangeable toolsets

Apply to various splice band material

Various applications all with a strong connection

Simple to operate

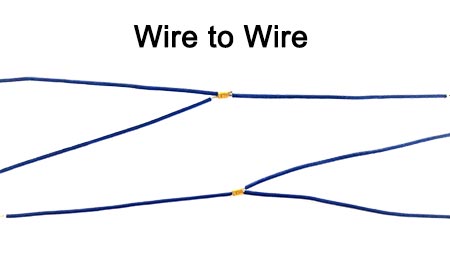

Splice Wires

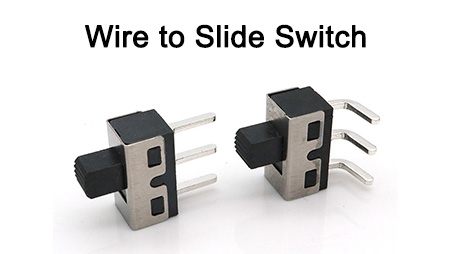

Splice Wire and Slide Switch

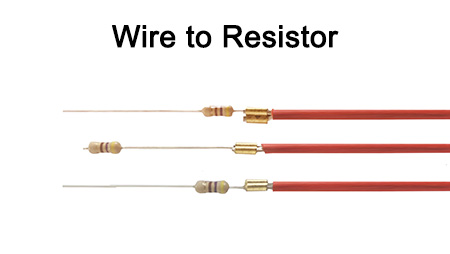

Wire to Resistor

JCW-2TA Electric Copper Tape Splicing Machine [ motorized feeding ]

Strong connection, vast applications, lowest applied cost, no scrapped material

Advantage of splice technology

The splicing technology is widely used in automotive, consumer, medical, and industrial electronics manufacturers. It offers reliable, efficient, and economical interconnection, which has obvious advantages like gas-tight, waste-free, repeatable and low resistance.

Meet highest quality requirements

1. Gas tight connection

2. No cold solder joint

3. No head impact to the components

4. No stiffening to the wire

5. Extremely low electrical resistance

6. Resistant against vibrations and shocks

7. Resistant against corrosion

8. Space-saving

Huge benefits, multiple applications

The JCW-2TA splice band crimping machine is a brand new model that utilizes an electrical splice band feeder, the splice band will be fed precisely. By fast tooling change, this splice band crimping machine is compatible with virtually all wire and cable types, numerous splice band materials, and sizes.

The machine's ability to feed, cut, form, and crimp eliminate the need for expensive pre-formed crimps, providing a stronger connection than solder and much faster than welding.

Multiple splice applications

- Wire to PCB connections, used in electronic devices

- D-BIT power jumper, multi-wire to PCB, provides low profile connection

- 3-post micro switch, used in automotive applications, replace soldering

- Multi-component splice, parallel circuit

- Multi-component jumper splice

- Sensor for utility meters

- Tungsten wire lead, used in UV light

- Multi-component series splice

- Textiles, fiberglass, plastics

| Model | JCW-2TA Electric Spliceband Splicing Machine |

| Function | Various splice band material, interchangeable toolsets, motorized splice band feeder |

| Spliceband | 1 - 6 MM in width, 0.25 - 0.5 MM in thickness |

| Band feeding length | Max 22 mm |

| Crimping force | 30 KN [ 3 tons ] |

| Stroke | 28 MM |

| Rated power | 750 W |

| OEM | Yes |

| Activation | Foot pedal |

| Power supply | AC 110 - 220V, 50 / 60 Hz |

| Dimensions | L 280 x W 380 x H 470 mm |

| Weight | 57 KG |

| CE-Conformity | Complies with CE equipment guidelines relative to mechanical and electrical safety and electromagnetic compatibility. |