Automatic Heavy-duty Multi-conductor Cable Cut & Strip Machine JCW-CS15N

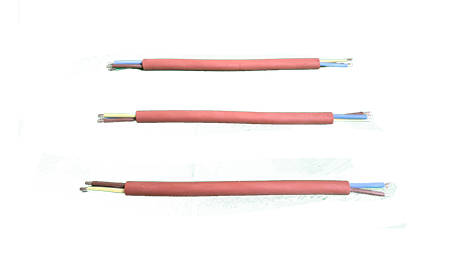

Focus on multicore cable, strip both layers, high reliability

Specialist in processing multicore cable

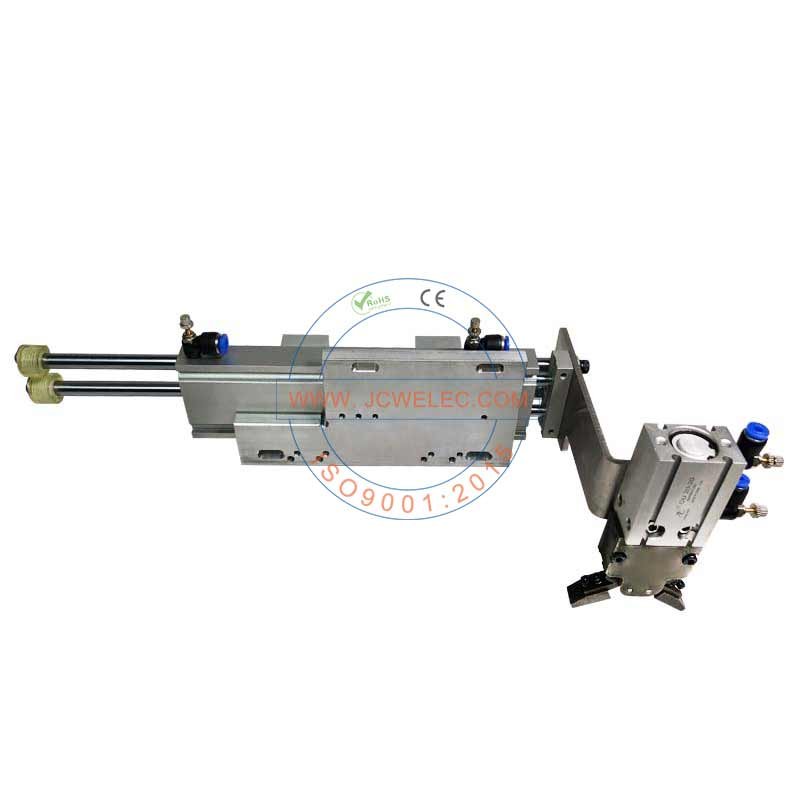

The JCW-CS15N cable cutting and stripping machine is updated based on JCW-CS15, it is capable of processing multicore cable up to 14mm O.D ( expandable to 25mm ), cutting and stripping both outer jacket and inner cores at one time perfectly. The unique shift cutter head carries 4 pieces of blades, processing outer jacket and inner cores separately allows big diameter cable and ensures high precision.

By fast-changing guide tubes, the JCW-CS15N cable cutting and stripping machine covers a wide cable range including PVC cable, Rubber H07RN-F cable, etc. This cut & strip machine also can be used for single wire up to 30 mm² ( expandable to 120mm² )

Easy to use

Each of the JCW-CS15N cutting and stripping machine comes with English display, the display language is customizable. A user-friendly interface and 7" color touchscreen make the operation so accurate and simple.

- The control with a touch screen has an intuitive user interface for simple and safe operation.

- The parameters such as wire cutting length, stripping length, wire diameter, speed, etc. can be accurately entered and stored for future recall at any time.

- Data library saves 100 programs, you can name each one by a wish.

- Automatic one-touch calibration function for cutting length.

- Cable run-out sensor gives the machine a stop signal while the cable is used out.

- Quickly change guide tubes and cutter blades.

- Transparent safety cover with sensor

- Ink jet printer

- Cable coiler

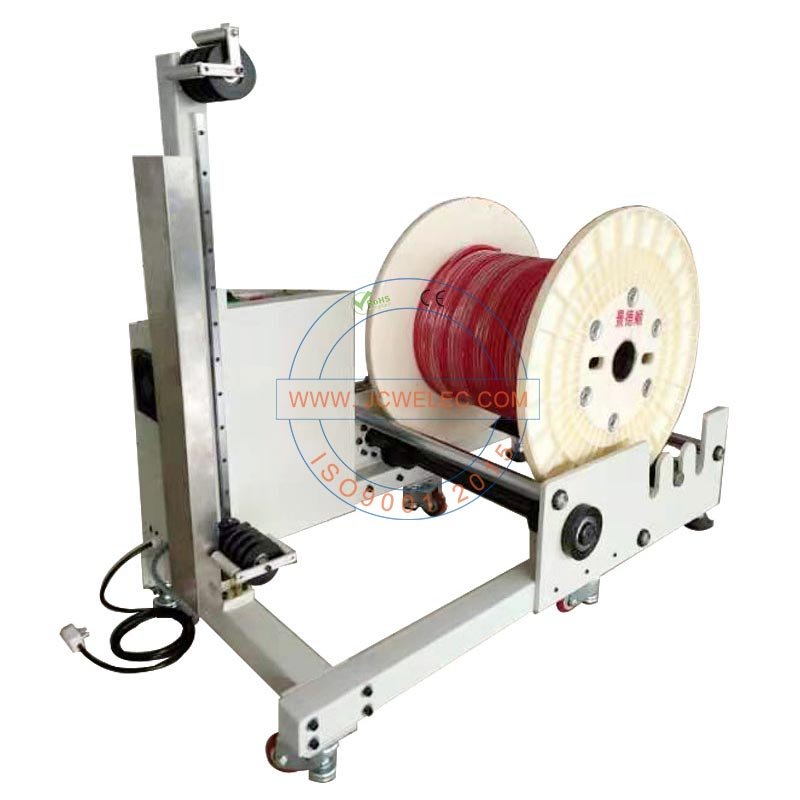

Build up your automated product line

Highly automated production lines play a more critical role in modern wire harness processing, greatly reducing labor costs and enhancing competitiveness.

- Wire unwind & pre-feed machine, load range from 15 to 1500 KG

- Robot arm controlled by CS15N

- Cable stacker, 1 meter to 6 meters

![Wire Stripping Twisting & Bootlace Ferrule Crimping Machine [ 4mm² ]](/data/thumb/res/en/20210829/2d8160410db52470.jpg_20210829092500_800x800.jpeg)

![Automatic Battery Cable Cutting Machine [ 8 Rollers ]](/data/thumb/res/en/20250509/jcwelec-cs05-cable-cut-strip-machine_1137102b.jpg_20250509172909_800x800.jpeg)