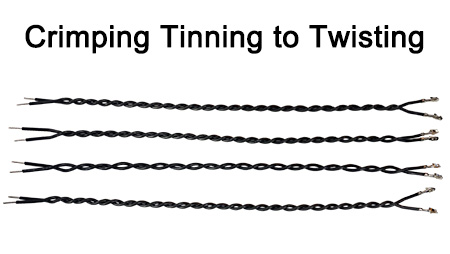

JCW-CST08 Fully-auto Wire Crimping, Tinning, and Twisting Machine

Smart design, fully programmable, high output

Maximum flexibility and compelling options

The JCW-CST08 enables a fully automated overall process from processing to the open wire ends. It enables the processing of 6 single wires (bulk goods) in a single step, twists 6 wires into 3 pairs. The standard model offers 850mm cutting length, 1200mm-1500mm-1800mm are all optional. Tinning can be turned off if it needs only wire stripping and terminal crimping.

The perfect process for the perfect wire

The JCW-CST08 is designed for meeting high output requirements. Fully automated processing, including crimping and twisting, enhances product security and stability. Parallel wire transfer ensures precise terminal crimping. The careful wire handling guarantees damage-free articles. They can be taken out of the wire deposit, ready for insertion.

High-quality processing and simple operations

The JCW-CST08 integrates high-quality components: 6 sets of servo motors, THK/TBI guide, FESTO valve, highly rigid transmission structure, high-speed control system. Super user-friendly interface and 7" touch screen interface offer accurate input and clear vision. A motorised digital wire twisting monitor brings perfect wire tinning. Vivid detectors ensure high-quality production: wire lack detection, wire knot detection, stripping detection, crimping detection, air pressure detection, etc.

Optional

- Crimping force monitoring ( CFM )

- 1200mm / 1500mm / 1800mm cutting length

- Wire prefeeder for keeping proper wire tension

- Customise HMI, language & logo